Now Reading: Green Energy Transition in Pakistan: Policy Framework for Industrial Efficiency

-

01

Green Energy Transition in Pakistan: Policy Framework for Industrial Efficiency

Green Energy Transition in Pakistan: Policy Framework for Industrial Efficiency

Introduction

Pakistan’s industrial sector, a key contributor for the nation’s economic progress, is still largely dependent on non-renewable sources of energy and inefficient energy consumption patterns. The reliance has resulted in higher operational expenses, the degradation of the environment, and decline in Pakistan’s positioning in the global marketplace. Chronic power shortages and the rising cost of fossil fuel imports further add to the imperative of a rapid shift towards cleaner energy resources. This policy brief analyzes the major obstacles impacting industrial energy efficiency in Pakistan and sets forth an integrated framework based on the incorporation of renewable energy, deployment of energy-efficient technologies, fiscal policy measures, and strategic public-private partnerships to facilitate a sustainable and green industrial transformation.

Current Energy Consumption Patterns and Challenges

The industrial sector in Pakistan forms almost one-fifth of the country’s Gross Domestic Product (GDP), but it utilized more than one-third of the overall energy resources of the country highly dependent upon natural gas, furnace oil, and foreign coal (Pakistan Economic Survey, 2023). Textile, cement, and steel industries have high-energy consumption rates, which create enormous greenhouse gas emissions along with increasing production costs. Additionally, inefficiency in energy use in industrial operations is reportedly responsible for 25-30% of unnecessary energy consumption (NEECA, 2022). Despite a number of green initiatives that have been implemented, the lack of comprehensive and enforceable industrial energy policy, minimal financial structures to fund green energy projects, as well as inefficient policy implementation mechanisms have hindered substantive progress towards cleaner energy usage.

Sectoral Energy Use and Emissions

As international supply chains increasingly focus on emission reduction, Pakistani industries are at an existential risk of losing their worldwide market competitiveness if rapid measures are not taken to improve energy methods in industries. It is crucial for Pakistan’s industries to be directed towards green energy solutions for both environmental conservation and the economic resilience and future growth of the country.

The pie chart demonstrates the rough breakdown of Pakistan’s energy usage across industries. The industrial sector is the highest consumer with almost 37% of the overall energy demand followed by the transport sector with 31%. Residential consumption occupies approximately 25% and agriculture and commercial sectors combined constitute less than 10% of the national energy pie. This decomposition underscores the skewed industry energy consumption underlining the observation presented in the policy brief that the industrial base of Pakistan especially energy guzzling industries such as textiles, cement and steel has a determining influence on the energy efficiency and sustainability performance of the country as a whole.

What’s unfortunate is that the excessive reliance on fossil fuels has exposed Pakistan’s industries to volatile production costs, compounded by international oil and gas price fluctuations. Imported fuel sources significantly account for Pakistan’s trade deficit, leaving industries vulnerable to external economic pressures. Many industrial plants continue to employ antiquated and inefficient machinery, resulting in exaggerated operational costs and unnecessary energy wastage. Small and Medium Enterprises (SMEs), specifically, are under capital constraints that limit their ability to fund efficiency improvement. Though there is a foundation-based presence of the Alternative and Renewable Energy (ARE) Policy 2019 and the National Energy Efficiency & Conservation Act 2016, there is a lack of specific regulatory guidelines that respond specifically to energy efficiency among industrial sectors. Compliance mechanisms in policy are poorly-enforced, and enterprises are insufficiently incentivized to adopt clean processes. The heavy upfront investments needed by clean energy technologies discourage industries from embracing clean solutions. The lack of dedicated green funding schemes, fiscal incentives, and incentive-based systems further hinders the road to energy efficient transitions.

Furthermore, a deep lack of internal technical skills among industrial actors remains, especially in the performance of energy efficiency audits and optimizing business workflows. SMEs lack availability of advisory services or technical support that would lead their shift toward more sustainable practices.

Global Best Practices and Lessons for Pakistan

The trend toward industrial energy efficiency is gathering pace around the world, fueled by increasing climate issues, more stringent environmental policies, and changing consumer expectations for greener products. India’s PAT (Perform, Achieve, Trade) Scheme and Germany’s Energiewende program are good examples of how green industrial transitions can be both made mandatory with a combination of regulatory requirements, offered economically through incentives, and driven by innovation. Such global best practices can be instituted in Pakistan by adapting them to its own industrial landscape, taking into account its energy resource basket, economic condition, and policy environment.

Economic and Employment Benefits of Industrial Energy Efficiency

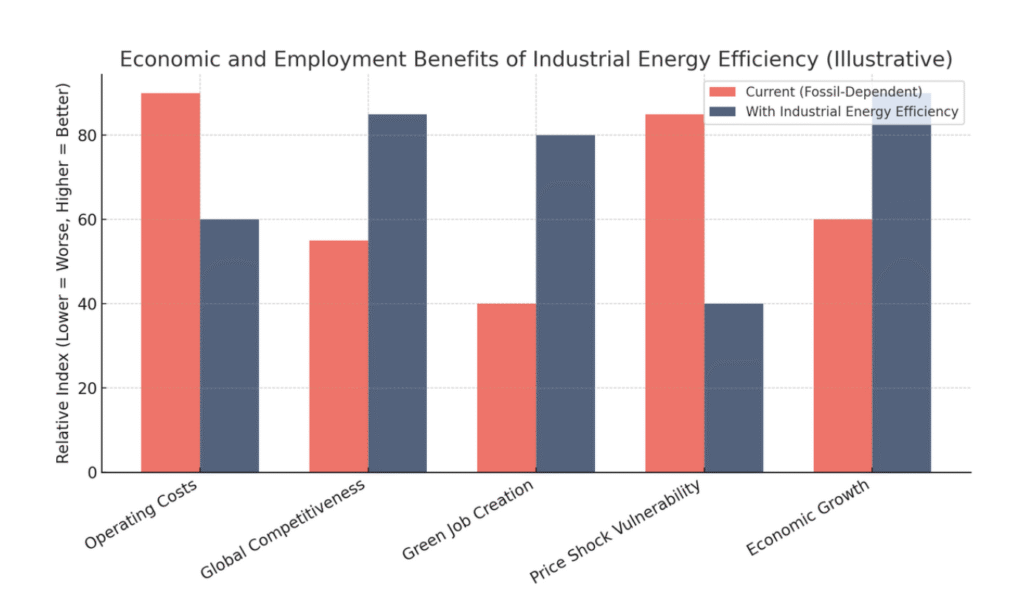

Enhancing industrial energy efficiency provides a range of economic advantages beyond simple cost savings. Through reducing operating energy costs, companies are able to increase competitiveness in international markets, especially for export-oriented industries such as manufacturing and textiles. Investments in efficient infrastructure also drive green job development, creating employment opportunities in industries such as renewable energy installation, retrofitting, and maintenance services. In the longer term, an increasingly energy-resilient industrial base lowers Pakistan’s exposure to international energy price shocks, stabilizes the cost of production, and aids economic growth.

Improving industrial energy efficiency creates a broad array of economic and job benefits that go well beyond mere cost savings. By reducing operating costs, industries can reduce their burdens on the bottom line and boost profitability, as well as improve their competitive position in global markets most notably export-oriented industries like textiles and manufacturing. Concurrently, efficiency-oriented investments create new opportunities for jobs, including green jobs associated with installing renewable energy, retrofitting, and maintenance services. Conversely, fossil fuel dependency makes Pakistan industries extremely susceptible to volatility in world oil and gas prices, subjecting businesses to price shocks that kill stability and growth. With energy efficient approaches and the addition of renewables, this vulnerability is lessened, allowing industries to be more resilient in operation. Overall, these joint impacts lead to long term economic stability, as a more energy resilient industrial base stabilizes production costs and allows for sustainable economic growth.

Institutional Reform and Governance Recommendations

A decentralized governance framework is one of the key impediments in implementing effective industrial energy efficiency measures in Pakistan. There is an imperative need to create a specific Industrial Energy Efficiency Authority (IEEA), which would be entrusted with preparing, implementing, and monitoring energy performance standards. This power should be coupled with provincial and local governments for policy cohesion and the resolution of jurisdictional overlap. The building up of institutional capacity through institutions such as NEECA by providing them with specialized training programs as well as resources will further consolidate the process of policy implementation.

Financing and International Support for Green Transition

One of the largest hurdles to improving energy performance in Pakistan’s industries is the issue of having access to affordable financing. This problem is specifically acute for small and medium organizations (SMEs), which often work with limited margins and struggle to put money into renewable technologies or contemporary equipments. Although regulations just like the Alternative and Renewable Energy (ARE) Policy 2019 offer a foundation, gaps in financing nevertheless save you meaningful development toward large-scale green transition. To cope with this, Pakistan needs to actively pursue worldwide climate financing possibilities. The Green Climate Fund (GCF), the World Bank’s Energy Sector Management Assistance Program (ESMAP), and the Asian Development Bank’s clean electricity projects already support developing countries via concessional loans and grants. Aligning national energy techniques with global commitments beneath the Paris Agreement could improve Pakistan’s chances of securing this guide and channeling it without delay into commercial reforms.

Another practical approach is the use of blended finance models, where public funds are combined with private sector investment and donor contributions. This approach lowers the risks for businesses that want to adopt green technologies. A good example would be setting up a Green Industrial Financing Facility, managed through local banks but supported by government guarantees and donor backing. Such a mechanism could provide concessional loans, leasing options, or credit guarantees, making it easier for industries especially SMEs to finance efficiency upgrades

Finally, international partnerships should not only focus on money but also on technical assistance and capacity building. Donor agencies and development partners can provide training, advisory services, and technology transfer programs that help local industries adopt modern energy practices. India’s Perform, Achieve, Trade (PAT) scheme is one example where financial incentives were paired with strong technical support to deliver results. Adapting such models to Pakistan’s industrial landscape would ensure that financial support translates into real, on the ground transformation.

Behavioral and Cultural Shifts for Energy Responsibility

Policy reforms as well as technology-based solutions will not be adequate without establishing a culture of energy responsibility among industrial actors. Behavioral change plays a crucial role in guaranteeing the success of energy efficiency programs. Governments, in association with exchange institutions and civil society, need to provoke mass awareness campaigns highlighting achievement testimonies of industries which have received from going inexperienced. Holding area-particular workshops, distributing toolkits

for energy control, and inspiring voluntary compliance through rewards schemes can bring behavioral adjustments at the economic level.

Strategic Policy Recommendations

The transition of Pakistan’s industrial sector towards green energy is not only an environmental imperative but also an economic imperative. A holistic, sectoral policy framework combined with vigorous regulatory enforcement, financial incentives, and capacity development programs can facilitate substantial industrial energy efficiency. Through public-private collaboration, as well as innovative financing and regulatory approaches, Pakistan can prepare its industries to be cost-effective, globally competitive, and environmentally sustainable. Adopting these policy interventions not only cuts Pakistan’s carbon footprint but also increases industrial efficiency, lowers energy imports, and adds to the nation’s long-term economic stability.

Author Name: SHEHARYAR KHALID